FELIXprinters Launches its most Robust & Reliable Pro 3D Printer for Industrial Applications: The Pro 3

January 14, 2019

We launched the Pro 3. How is it different from the Pro 2?

January 31, 2019Background

Based in the UK, RotaScan offers a wide range of engineering services for myriad industrial sectors including aerospace, instrumentation & control, power generation, automation, inspection and medical devices. A core competency of RotaScan is the use of a range of product development and manufacturing tools combined with decades of expertise to deliver successful projects for its clients.

As an independent company that originally was formed to fulfill contracts to the Ministry of Defence and ‘Blue Sky’ research, RotaScan was founded by Jonathan Sullivan, who leads project focused teams that offer a diverse range of skills & capabilities aimed at supporting clients with product development, research, prototyping, testing, diagnostics and pre-production activities. As a result, RotaScan has been involved with many projects from start to finish, but has also been commissioned to apply its expertise when difficulties arise in projects, which they invariably do, in order to find solutions and provide effective short-term support. And, the company is good at it, which has resulted in RotaScan establishing a stellar reputation in this area.

The spectrum of services that RotaScan offers includes, but is not limited to, 3D design & solid modelling, mechanical design, Fluid Dynamics, simulation, failure analysis, competitive testing, prototyping, light CNC machining, traditional turning / milling, laser cutting, engraving, marking, and of course 3D printing.

Jonathan Sullivan, who leads RotaScan from the front, qualified with degrees in Mechanical Engineering and also Electronics & Systems, has worked across the World with some fascinating companies large and small. For many years he gained experience and insight into many industrial sectors working for a range of Super Industrials, including Renishaw, De La Rue and QinetiQ (previously DERA), in the UK. Additionally, providing consultancy to Oxford, Cambridge and Naples (Italy) Universities, the Ministry of Defence (UK) and the Department of Defense (USA).

Jonathan Sullivan, who leads RotaScan from the front, qualified with degrees in Mechanical Engineering and also Electronics & Systems, has worked across the World with some fascinating companies large and small. For many years he gained experience and insight into many industrial sectors working for a range of Super Industrials, including Renishaw, De La Rue and QinetiQ (previously DERA), in the UK. Additionally, providing consultancy to Oxford, Cambridge and Naples (Italy) Universities, the Ministry of Defence (UK) and the Department of Defense (USA).

He was able to gain a wealth of experience along the way as new technologies emerged for developing new products and was a seasoned designer on 3D CAD systems for over 20 years. Jonathan has specialised in the field of Agile design philosophy, to very quickly progress concepts, to models, to real commercial products. Without a lot of fuss, cost and delays.

3D Printing Essential for RotaScan

For RotaScan 3D printing is a ‘must have’ tool for its fast and efficient prototyping capabilities. Prototyping, today, remains the largest industrial application of 3D printing technology, and has proved invaluable for RotaScan in this regard.

As Jonathan explained: “The ability to transfer 3D designs to a physical 3D print is so powerful. We have shown parts to customers that were originally 6 months away and looking at £5M further investment, traditionally to find out what the result was! We modelled the parts in days and designed test rig options way before costly decisions are set in stone.”

Product development — and all the disciplines that it incorporates — for high value, critical projects typically incur high costs with a raft of risks. Thus, getting the development of parts and components right and fit for purpose as soon as possible in the product development process goes a long way to mitigate these issues and, according to Jonathan, reliable 3D printing is a key enabler for this in his business.

FELIXprinters Meets the Need – Fast AND Reliable

Six years ago, RotaScan purchased its first FELIX 3D printer, and it has been a steady and reliable workhorse since. Jonathan describes it as “a go-to tool for working models” Of course, RotaScan operates in the real world, and the company’s workshop utilises a range of other tools as well, but for fast prototypes for physical assessment and testing, it is a fundamental tool. Moreover, the FELIX 3D printer is vital to RotaScan in terms of saving time and money to prove a concept and demonstrate it in the real world through its reliability and ability to cope with ‘difficult’ prints where the machine choice makes all the difference.

Six years ago, RotaScan purchased its first FELIX 3D printer, and it has been a steady and reliable workhorse since. Jonathan describes it as “a go-to tool for working models” Of course, RotaScan operates in the real world, and the company’s workshop utilises a range of other tools as well, but for fast prototypes for physical assessment and testing, it is a fundamental tool. Moreover, the FELIX 3D printer is vital to RotaScan in terms of saving time and money to prove a concept and demonstrate it in the real world through its reliability and ability to cope with ‘difficult’ prints where the machine choice makes all the difference.

Jonathan relates: “The complexity of many of our projects is a great fit for 3D printing, and the FELIX 3D printer meets our needs. We choose our tools very carefully and when we were looking at purchasing a 3D printer for the first time, it was like walking in to candy shop — there are so many to choose from! I made the decisions and went beneath the surface — as well as considering the total machine build. The FELIXprinters have a rigid, Aluminium structure, which many other systems in the same category do not have. Also, when I inspected the FELIX products more closely, it’s obvious that they have been designed very carefully by smart engineers for discerning professional customers and if you are a high-end hobbyist, you will not be disappointed.”

He continued: “Mechanically, FELIXprinters have considered the full architecture of the system, so that dynamic loads are as light as possible, which is in contrast to cross-gantry machines where one axis carries another axis, multiplying errors and sacrificing performance.

It is undoubtedly a quality machine. We bought this machine as ‘try’ in a kit form. Not only was it quite enjoyable, it was very instructive. How does additive manufacturing work? It changes the mindset. The FELIX printer was the best investment in technology we have ever made.”

“We did study the whole market in this product space. There were some good-looking machines, but without exception, they all did not have the vital components, rigid frame, precision linear guides and superb smart design like optical limit switches, replacement printables, high duty steppers and more”

Another key positive for Jonathan was the reliability of the machine, fitted with an E3D full Metal print head: “I can honestly say, with sensible maintenance, it has never jammed or let me down. Running prints for over 24 hours doesn’t worry me. It is extremely satisfying to see your machine working whilst you take care of other business.”

The FELIX Philosophy

He puts this down to the philosophy and operational expertise of FELIX as a company. “As an organisation they are very clean thinking and straightforward, at least that’s my experience. And as I said, they are obviously engineers that understand the operating expectations and performance requirements out in the field. The mechanical auto-levelling of the recent PRO Series system, for example — it’s just so intuitively right, particularly when compared with the standard software levelling of other machines which just bend geometry. The construction is solid and reliable – which is a fundamental requirement. And the 3D printer is not confused — everything is constructed for optimal performance and reliability. And over the years (since I’ve operated our first machine) the progression and evolution of the machines has been progressive and impressive.”

Even weighing up the fact that the FELIX 3D printers are not competing on capital costs in the familiar ‘race to to bottom’ in the desktop 3D printer space, Jonathan was totally unphased: “They’re not the cheapest machines out there, certainly, but they are the best value for money I have come across, investing twice because a purchase decision was wrong, is not an option for us. Also, the support team are fantastic – with fast responses and good, real information. They really know what they’re talking about.”

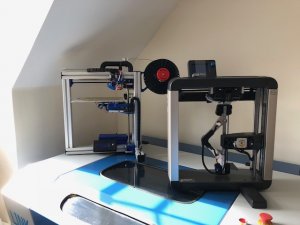

RotaScan has just acquired a second machine, this time dual head in the Pro Series, from FELIXprinters. According to Jonathan: “We’ve held off from dual head printing until now because of many of the issues raised by running two heads that actually work together. FELIXprinters have designed firmware and the mechanics from the beginning, all neatly integrated in to a coherent system.

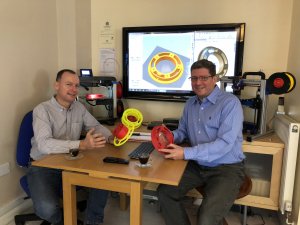

Earlier, I was not confident that the whole process could work seamlessly. But the combination of Simplyfy3D and FELIXprinters’ innovative solution to this has convinced me — again, it just makes sense, with the automated shift for the printhead that is not being used. With all automatic calibration tools too, it’s just the right way to do it. It is an excellent product and we are very pleased to offer our capabilities using this machine. We’ve just secured a new design contract for a Human Medical Implant product. Our customer requested that we produce Proof of Concept (POC) examples on the Felix Pro2 after I showed off some demo parts we had prepared”

Earlier, I was not confident that the whole process could work seamlessly. But the combination of Simplyfy3D and FELIXprinters’ innovative solution to this has convinced me — again, it just makes sense, with the automated shift for the printhead that is not being used. With all automatic calibration tools too, it’s just the right way to do it. It is an excellent product and we are very pleased to offer our capabilities using this machine. We’ve just secured a new design contract for a Human Medical Implant product. Our customer requested that we produce Proof of Concept (POC) examples on the Felix Pro2 after I showed off some demo parts we had prepared”

The new FELIX Pro 2 will be consistently utilized at RotaScan to support its service offerings for Design, Workshop and Lab. The FELIX machines are an important platform in our set of capabilities.